6mm shank cylinder felt bob

| Item: | 6mm Medium Cone-Shape Wool Felt Bob Polishing Rotary Cusp Point |

| Material: | 100% Wool |

| Diameter: | 40mm |

| Shank Size: | 3mm (1/8”) , 6mm(1/4”) |

| Used with: | electric drills, electric grinders or other rotary tools and grease-less, or standard buffing compounds. |

| Typical Application: | Polishing Glass, Marble, Stainless steel, etc. |

1)felt polisher bob, dental felt bob, felt bob, high-quality fine abrasive with diamond and polishing agents.

2)The felt with handle is specially applicable to the grinding of high quality mirror surface, very practicability. and suitable for working whith samll hand tools to undertake deburring, highlighting and polishing of any hard to reach areas.

3)Widely used in the cylinder bore grinding, glass, pipe, abrasive, mold, medical equiment, beauty equipment, gold and silver jewelry, stainless steel, etc.

Q: Why using felt bobs for polishing?

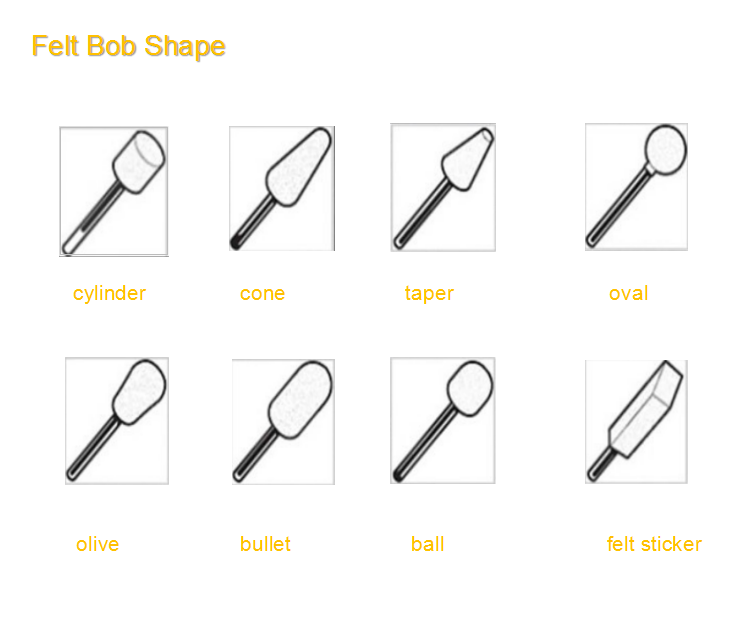

A: Felt Bobs can be any shape and small, to match the small surface.

Wool felt have better capability than other materials to accept the various polishing compounds and slurry.

when the felt surface wears, new surface has form and hold the polishing compound to continue the polishing work. The felt surface does not get glazed.

Q: How to choose the density of felt bobs ?

A: If the condition of surface is good, very little scratches, the hard density could be using. If the surface condition is not good, with significant scratches, then using soft density of felt bobs.

Always remember: The softer the wheel, the better for high luster or final result.

Q: How to store the felt bobs after finishing the work?

A: Allow the felt bob to continue to spin thru for several minutes so any remaining polishing compound residue can spit out. Then let the felt bob air dry before storing it to prevent molds.